Page 261 - Technical Cooperation Project for Building Capacity for Can Tho University...

P. 261

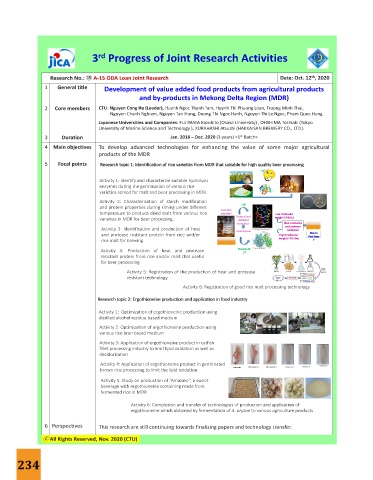

3 Progress of Joint Research Activities

rd

Research No.: ⑮ A-15 ODA Loan Joint Research Date: Oct. 12 , 2020

th

1 General title Development of value added food products from agricultural products

and by-products in Mekong Delta Region (MDR)

2 Core members CTU: Nguyen Cong Ha (Leader), Huynh Ngoc Thanh Tam, Huynh Thi Phuong Loan, Truong Minh Thai,

Nguyen Chanh Nghiem, Nguyen Tan Hung, Duong Thi Ngoc Hanh, Nguyen Thi Le Ngoc, Pham Quoc Hung

Japanese Universities and Companies: FUJIYAMA Kazuhito (Osaka University) , OHSHIMA Toshiaki (Tokyo

University of Marine Science and Technology ), KURAHASHI Atsushi (HAKKAISAN BREWERY CO., LTD.)

3 Duration Jan. 2018 – Dec. 2020 (3 years) <1 Batch>

st

4 Main objectives To develop advanced technologies for enhancing the value of some major agricultural

products of the MDR

5 Focal points R Reesseeaarrcchh ttooppiicc 11:: IIddeennttiiffiiccaattiioonn ooff rriiccee vvaarriieettiieess ffrroomm MMDDRR tthhaatt ssuuiittaabbllee ffoorr hhiigghh qquuaalliittyy bbeeeerr pprroocceessssiinngg

Activity 1: Identify and characterize suitable hydrolysis

enzymes during the germination of various rice

varieties served for malt and beer processing in MDR.

Activity 2: Characterization of starch modification

and protein properties during kilning under different Function L LTTPP

temperature to produce dried malt from various rice peptides L Looww mmoolleeccuullaarr

varieties in MDR for beer processing. Formed and w weeiigghhtt ((~~99 kkDDaa))

stabilized

foam beer H Heeaatt rreessiissttaannccee

Activity 3: Identification and production of heat Quality beer a anndd pprrootteeaassee

r reessiissttaannccee

R Riiccee iinn

and protease resistant protein from rice and/or H Hiigghhtt mmoolleeccuullaarr V Viieett NNaamm

rice malt for brewing w weeiigghhtt ((~~4433 kkDDaa)) ? ?

Activity 4: Production of heat and protease P Prrootteeiinn ZZ44,,

Z Z77

resistant protein from rice and/or malt that useful

for beer processing

Activity 5: Registration of the production of heat and protease

resistant technology.

Activity 6: Registration of good rice malt processing technology

R Reesseeaarrcchh ttooppiicc 22:: EErrggootthhiioonneeiinnee pprroodduuccttiioonn aanndd aapppplliiccaattiioonn iinn ffoooodd iinndduussttrryy

Activity 1: Optimization of ergothioneine production using

distilled alcohol residue based medium

Activity 2: Optimization of ergothioneine production using

various rice bran based medium

Activity 3: Application of ergothioneine product in catfish

fillet processing industry to limit lipid oxidation as well as

decolorization

Activity 4: Application of ergothioneine product in germinated Frozen 2 m Frozen 3 m

brown rice processing to limit the lipid oxidation Catfish fillet After washed 1 After washed 2 Frozen 1 m

Activity 5. Study on production of “Amazake”, a sweet

beverage with ergothioneine containing made from

fermented rice in MDR

Activity 6: Completion and transfer of technologies of production and application of

ergothioneine which obtained by fermentation of A. oryzae to various agriculture products

6 Perspectives This research are still continuing towards finalizing papers and technology transfer.

ⓒ All Rights Reserved, Nov. 2020 (CTU)

234